Vacuum freeze dryer is widely used in medicine, pharmacy, biology research, chemical industry and food production, etc. After freeze drying process, a long-term preservation for material is much easier. They can be restored to original state and maintain their chemical and biological characteristics after being watered.

FD-10 freeze dryers, small amount of samples can pre-freeze in condenser. They are suitable for lab use or small-scale production, and they can meet requirements for most laboratories.

Features

1. All-in-one structure, small size, no external flange, easy to use, no leakage.

2. All materials in contact with the product use inert materials to meet the requirements of the GLP.

3. The cold trap and console are made of stainless steel, which is anti-corrosion and easy to clean.

4. All stainless steel inflated/water release valve is designed and produced by our company, which is safety, anti- corrosion, no leakage.

5. With sample pre-frozen function, large cold trap opening, no inner coil, and low temperature refrigerator is needless.

6. Patented gas diversion technology, and strong ice holding ability.

7. World - known brand compressors, high efficiency, long life, low noise.

8. Well-known brand vacuum pump with a high pumping speed to achieve a higher ultimate vacuum.

9. Vacuum pump protection function can set the cold trap temperature to protect the vacuum pump life.

10. Professionally designed FD-LAB freeze-drying machine control system + SH-HPSC-I modular controller with high reliability and stability.

11. Intelligent data recording system can real-time record and display the cold trap temperature curve, sample temperature curve, vacuum curve.

Optional accessories and functions

1. Cold trap temperature -80℃

2. Vacuum pump anti-return device

3. Cold trap electric heating defrosting

4. Oil mist filtration system

5. 50 ml eggplant bottle

6. Wide-mouth bottle device (600ml/1200ml)

7. International brand vacuum pump

8. Non-standard customization

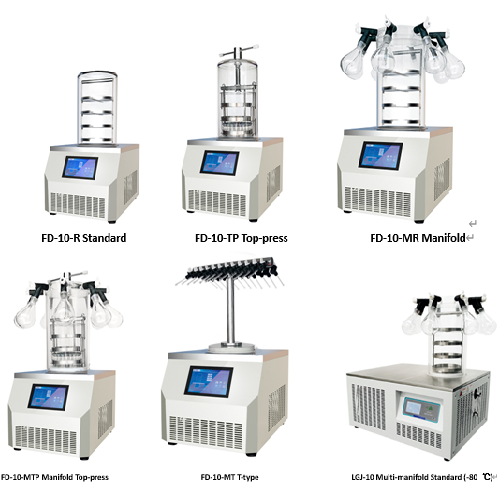

Model Selection Guide

R. Standard:

It is suitable for freeze-drying bulk (liquid, pasty, solid) conventional materials.

TP. Top-press:

It is not only suitable for freeze-drying of bulk (liquid, pasty, solid) conventional substances, but also suitable for drying of Vials materials. When preparing for freeze-drying, the materials are separated into Vials according to the need. After floating the cap, the freeze-drying process start. After drying, the capping device is operated to tighten the cap, which can avoid secondary pollution, re-adsorb water, and is easy to store for a long time.

MR. Multi manifold general type:

It is suitable for the freeze-drying of bulk (liquid, pasty, solid) conventional materials, and can be fitted with flasks outside the drying chamber to dry the materials rotated inside the bottle wall. At this time, the flask is connected to the manifold outside the drying chamber as a container. The material in the flask is heated at room temperature. Through the multi-manifold switch device, the flask can be removed or loaded at any time as needed without stopping the machine.

MTP. Multi manifold cover type:

On the basis of the characteristics of the common type, it combines the characteristics of the capping type and the common type of multi-weir pipe. It is suitable for freeze-drying of bulk (liquid, pasty, solid) conventional material; suitable for drying of vials materials.

When preparing for freeze-drying, the materials are separated into vials according to the need. After floating the cap, the freeze-drying process start. After drying, the capping device is operated to tighten the cap, which can avoid secondary pollution, re-adsorb water, and is easy to be stored for a long time. The flask is used to dry the material whirled inside the flask. At this time, the flask is connected to the manifold outside the drying chamber as a container. The material in the flask is heated at room temperature. Through the multimanifold switch device, the flask can be removed or loaded at any time as needed without stopping the machine.

MT. T shelf:

It is suitable for the preservation of microorganisms such as bacteria and fungi in ampoule tubes. The ampoule storage method is often used in laboratories. The samples were packaged in small ampoules after freeze-drying. It has the advantages of Long-term preservation, small variation, easy storage and Widely used.

Technical index

Model | FD-10 | ||||

Specification | Unit | FD-10-R Standard | FD-10-MR Manifold | FD-10-TP Top-press | FD-10-MTP Manifold Top-press |

Freeze-drying area | ㎡ | 0.12 | 0.12 | 0.08 | 0.08 |

Cold trap temperature | ℃ | < -56 (no-loading), option < -80 (no-loading) | |||

Vacuum degree | Pa | ≤ 5 (no-loading) | |||

Water-capture capability | kg/24h | 3-4 | |||

Tray dimension | mm | φ200 | φ180 | ||

Trays number | pcs | 4 | 3 | ||

Tray spacing | mm | 70 | |||

Power | w | 970 | |||

Weight | kg | 41 | |||

Dimension (-56℃ ) | mm | 615×450×370 | |||

Dimension (-80℃ ) | mm | 850×680×405 | |||

Drying chamber size | mm | Ф260×430 | Ф260 × 430 + flask interface: 8pcs | Ф260×490 | Ф260 × 490 + flask interface: 8pcs |

Diameter of cold trap | mm | Ф215 | |||

Cold trap depth | mm | 140 | |||

Bulk capacity (thickness 10mm) | L | 1.2 | 0.8 | ||

Vial loading number | pcs | - | Ф12mm:492 | ||

pcs | - | Ф16mm:297 | |||

pcs | - | Ф22mm:147 | |||

Defrosting | - | Natural defrosting (option electric defrosting) | |||

Power | - | 1Ph + N + PE, 220V | |||

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Lisy

Phone: 001-719-3091089

E-mail: info@uslab.us

Add: 1658 Garden of the Gods Road, Colorado Springs, Colorado 80907, USA